We are Atcom Corporation

In Sanskrit, "Atcom" signifies excellence - a term that not only defines our brand but also

embodiesour

philosophy.

Our brand is  . We understand that the right industrial valve solution

can make all the difference in the smooth operation of your business processes.

. We understand that the right industrial valve solution

can make all the difference in the smooth operation of your business processes.

We believe

that exceptional quality and reliable performance are the keys to driving successful outcomes in

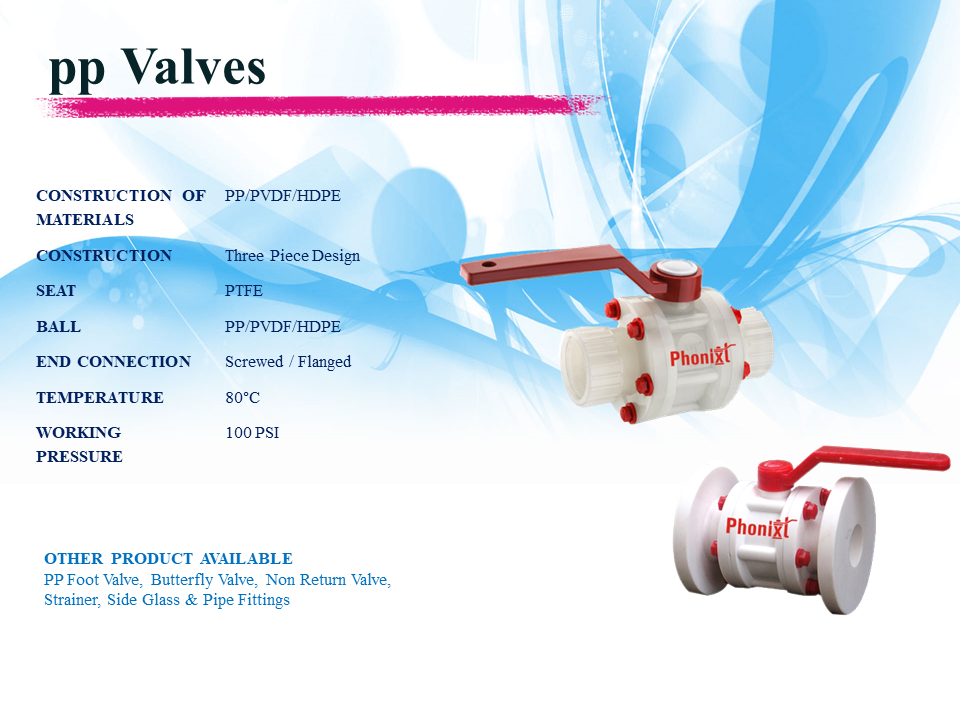

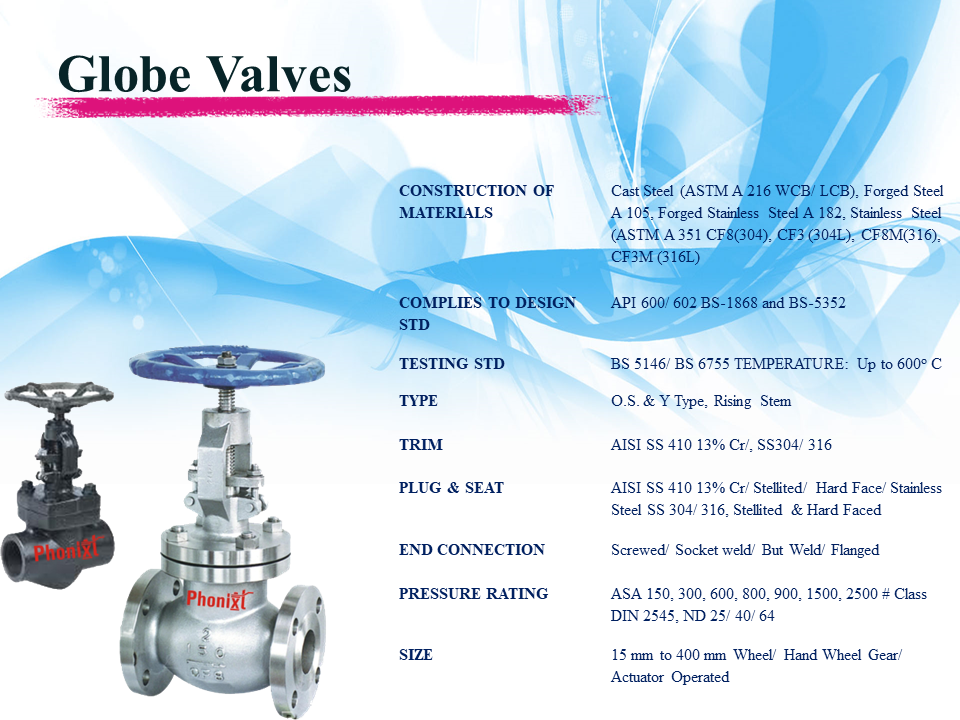

any industry. Upholding international standards such as ASTM, BS, DIN, API, API6D, and ASA, we

founded Atcom Corporation to help you achieve optimal efficiency and safety in your operations by

providing top-notch industrial valve solutions tailored to your unique needs.

Experience the

Atcom difference and let our dedication to engineering excellence and customer satisfaction be the

driving force behind your business success. We are Atcom Corporation, a privately-owned company and

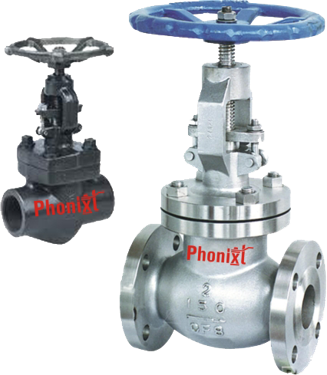

a leading manufacturer of industrial valves, strainer & sight glass (double window sight glass) in

India.

Our mission is to provide top-quality products at highly competitive prices to

industries in India and across the globe. Our versatile valves cater to diverse industries such as

process & chemical, refineries & petrochemicals, fertilizers, pharmaceuticals, power generation,

textiles, paints, sugar, breweries, detergents, steel, food & oil, water treatment, shipyards,

marine management, pulp & paper, LPG bottling plants, and slurry & ash handling.

Our

in-house engineering team is experts in valve modification and recertification and has the ability

to change the design and specification of valves to suit your requirements.

WHY US?

- We use Quality Raw Materials (Castings & Forgings ) from reputed foundries/forge shops and we have Statistical Quality Assurance system with inspection at every stage of Manufacture to ensure sustained quality in our supplies.

- We have adequate capacity in terms of expertise and finance are in a position to undertake large volume of orders with committed deliveries.

- Achieve continual business growth by increasing Customer Satisfaction.

- On time delivery.

- Minimization of Custom Complaints.

- Reduce rework and save quality Loss.

Quality and Integrity

- Premium Materials: Use of carbon steel, stainless steel, and cast iron for durability.

- Compliance: Products meet industry standards like ASTM, ASA, and DIN.

- Stringent Testing: Adherence to BS and API testing standards.

- Stringent Testing: Adherence to BS and API testing standards.

- Reliable Performance: Ensuring optimal performance under various conditions.

- Customer Commitment: Delivering excellence to meet customer demands.

Best Prices In The Market

- Phonix Valves offers competitive pricing and exceptional service.

- Our extensive dealer network ensures prompt sales and after-sales support in all over India.

- Our dedicated Marketing & Sales Manager leads this setup, ensuring customer satisfaction across all regions.